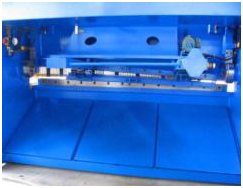

Shearing Machine

Main function:

- The control behind

- General motors’ or inverter control

- Intelligent positioning

- Two programmable digital output

- Yard and meter turn

- Artifacts count

- 40 program storage each step 25

- Unilateral positioning

- A key to parameter backup and recovery

| Technical Parameter | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| No. | Name | Numerical value | unit | Notes | |||||||

| 1 | Max. cutting thickness | 4 | mm | ||||||||

| 2 | Max. cutting width | 1600 | mm | ||||||||

| 3 | Cut material strength | 450 | N/mm2 | ||||||||

| 4 | shear angle | 30′-1°30′ | |||||||||

| 5 | Stopper adjust range | 20-500 | mm | ||||||||

| 6 | Number of strokes | 8 | min-1 | ||||||||

| 7 | Distance between frames | 3360 | |||||||||

| 8 | Blade length | 3200 | |||||||||

| 9 | Worktable height | 850 | |||||||||

| 10 | Main motor | ||||||||||

| Power | 11 | KW | |||||||||

| Rotate speed | 960 | R/min | |||||||||

| 11 | The motor behind | ||||||||||

| Power | 0.55 | KW | |||||||||

| Rotate speed | 900 | R/min | |||||||||

| 12 | Axial piston pump | B3 Double the shaft | |||||||||

| Flow | 40 | L/min | |||||||||

| Pressure | 31.5 | Mpa | |||||||||

| 13 | Dimension | Length | 3800 | mm | |||||||

| Width | 2200 | mm | |||||||||

| Height | 2800 | mm | |||||||||

Blanking plate |

Liner guide rail,high precision |

gear pump |

Tubing |

Adjusting the gap |

Safety guide |

welded-steel plate construction |

Panel shows the back gauge distance |

Universal ball,easy for feeding |

| Main out-purchased listing | ||

|---|---|---|

|

No. |

Name |

Supplier |

|

1 |

CnC system |

ESTUN |

|

2 |

Hydraulic control system |

Shanghai liquid 2 |

|

3 |

High pressure plunger pump |

Shanghai Hangfa |

|

4 |

Tubing connector of cutting sleeve type |

EATON |

|

5 |

Linear guide way |

PMI-AMT |

|

6 |

Balls crew |

|

|

7 |

Oil cylinder sealing element |

Japan NOK |

|

8 |

Single/double air switch |

French Schneider |

|

9 |

A.C. contactor |

|

|

10 |

Thermorelay |

|

|

11 |

Breaker |

|

|

12 |

Oil cylinder |

Shanghai hering |

|

13 |

Blade |

Paul Everitt (Germany) |

|

14 |

Foot operated Device |

|

|

15 |

Complete control panel made of imported parts |

|

Structural features The fuselage through FEM after the finite element analysis of frame structure

- Welding structure box body design makes the body have the greatest strength and rigidity.

- Adopt world-class bearing, high precision and free maintenance.

- High pressure oil pump adopts the axial plunger pump made in Shanghai, compact structure, small size light weight stable running, low noise characteristics of small flow pulsation of.

- Oil cylinder adopt boring, reaming, such as rolling mill close processing technology, Surface roughness Ra 1 0.4 um, the piston and seals supporting pieces can move smoothly and ensure the sealing effect. Reduce wear to extend the service life. In order to prevent corrosion in cylinder surface chromium plating. Japan NOK seal oil seal adopted.

- Hydraulic valve group, shearing machine special complete valve group adopts advanced two-way cartridge valve integrated system, simple structure, flow ability, low leakage, stable operation, low noise, is unmatched by ordinary hydraulic valve

- Knife mold Shanghai ivey TeEr high-quality cutting tool material (6 crw2si) on the top and bottom high carbon high chromium steel, long service

- Machine tool electrical motor and solenoid valve control system USES the French schneider electric company produce ac contactor - intermediate relay long life high

- Machine precision and technical conditions in accordance with GB/he and JB5497 T14004-93-93

Training Equipment

- Automobile engine training device.

- Automobile structure training equipment.

- Automotive dissection model.

- Automotive electrical system training device.

- Electric vehicle training device.